In India, a very few manufacturing units offer tooling and machining facilities and among them just a handful have international standards in tooling, JIG, and component machining. A tooling design facility, also known as a tool and die shop is a specialized manufacturing unit well-equipped with all required tools and equipment for the design and fabrication of tools, molds, dies, and precision-machined gears, apparatuses, and components for various industrial uses. The in-house tooling design & manufacturing facilities of the advanced composites are an added advantage for various industries in automotive, railways, marine, aerospace, luxury bikes, sports bikes, and many more.

What is tooling?

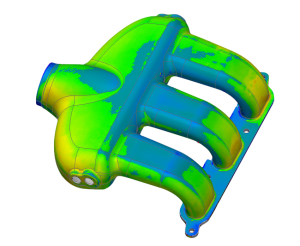

In Industries of automotive, aerospace, marine, and heavy engineering require various complex tools for manufacturing purposes. These are not ordinary tools but are precisely designed for manufacturing purposes. Let’s take an example, a luxury sports car manufacturers need specialized tools and components from manufacturing luxury sports cars. Depending on the design and mechanical abilities, the manufacturers need specific tools solely designed for that manufacturer.

Customized tools are required in almost every industry involved in the manufacturing of complex machines. This facility of in-house tooling design & manufacturing facility of an advanced composite solutions with decades of experience is provided by Rockman Advanced Composites. Making customized tooling and machining easier and cost-effective. Tooling can include dies, molds, jigs, fixtures, and cutting tools.

- Dies and molds are used mainly for stamping and casting raw materials into finished parts. These are also used to develop basic components for automotive units or components for other complex machine parts.

- Jigs and fixtures have different roles in manufacturing of automotive, marine, Defense, aerospace, and medical applications. Jigs and fixtures are mainly used to hold and guide various workpieces during machine and assembly processes. They ensure the proper placement of the workpieces and the highest level of accuracy.

- Tooling design also includes designing high-precision cutting tools. Cutting tools like lathes, drills, and mills are customized tools essential in different industries for precision machining.

Rockman Advanced Composites has the capabilities of designing, programming, and machining patterns, molds, jigs, and composite components.

What is machining?

Machining plays an important part in getting high-precision components for more complex machine parts often used in industries like automotive, railways, marine, heavy engineering, medical appliances manufacturing, and aerospace. Through machining, workpieces are given the final shapes. Machining is also required for surface finishing.

With the high-quality, international standard in-house tools design & manufacturing, the service providers in this field now offer machining with epoxy tooling boards, MDF, aluminum, and SS & Invar. The most common machining processes include Milling, Grinding, Turning, CNC machining, and EDM.

- Milling is often used to get complex shapes of machine parts used in the many industries. In the milling machines, designed rotating cutters are used to cut extra materials from a workpiece.

- Grinding machines are mainly used to remove granular parts from the metal surfaces to give the metal a fine polished finish.

- Turning machines are used to provide a cylindrical shape to a metal part. These are mostly used in highly complex machine parts.

- CNC machining is one of the most advanced machining where computer-operated machines are used to control the machining processes.

Tooling and machining are indispensable parts of variuous industries. Rockman Advanced Composited is an expert in in-house tooling design & manufacturing. They have a state-of-the-art facility to design high-quality tools and machining components for various industries as stated before. The quality and workability of these tools and machining components make the jobs easier and faster for the manufacturers.