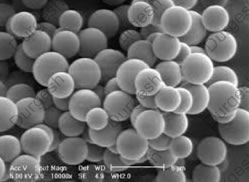

Once considered a mere byproduct and sometimes waste material produced from coal combustion, cenospheres are now considered a multipurpose and highly valuable material with diverse industrial applications. These microscopic, hollow byproducts of coal combustion boast exceptional properties making them a game-changer in various manufacturing processes including oilfields, construction projects, automotive, plastics and polymers manufacturing, and oil well cementing. Durgesh Group is the leading Cenosphere exporter from India offering a consistent supply of high-quality cenospheres.

Advantages of Cenospheres

One of the primary advantages of cenospheres is their remarkably low density. Cenospheres are mainly composed of aluminum silicate that is lighter than traditional fillers such as glass beads and sand. This makes a material or product filled with cenospheres lighter than when filled with traditional fillers. Cenospehers have high demand in various buoyancy applications such as marine industry, oil and gas exploration, aquaculture, autonomous underwater vehicles, underwater research instruments, and underwater construction.

Cenospheres are excellent thermal insulators. Its hollow structure effectively traps air obstructing the transfer of heat and improving energy efficiency of the system as a whole. This special feature of this material makes it an excellent product for construction projects. It is now frequently used in the construction industry for manufacturing lightweight concrete for building houses with better thermal insulation and reduced energy consumption. Top-graded cenosphere exporter from India now exports best quality cenospheres that are 75% lighter than other minerals currently used as fillers and 30% lighter than resins.

Though the material, a byproduct of coal combustion, possesses low density, it has remarkably high compressive strength. For this feature, cenospheres are often added to composites and coatings to enhance the lifespans of those composites and coatings.

Another remarkable advantage of this lightweight byproduct of coal combustion is its chemical inertness. Cenospheres are corrosion-resistant and don’t damage easily. This material is suitable for various industrial applications in adverse weather conditions and harsh man-made environments. They enhance the longevity of wall paints and coatings. Cenospheres are also used in medical applications like bone implants, drug delivery systems, tissue engineering scaffolds, dental fillings, and prosthetic applications.

All the above-mentioned advantages of cenospheres make it a noteworthy sustainable material. Proper application of cenospheres offers an opportunity to transform waste into a treasured resource. The lightweight of the material lowers transportation costs and reduces the consumption of various resources during their applications.

How cenospheres are manufactured?

This amazing material is not manufactured technically but collected in a systematic way from coal fly ash. The burning of coal or coal combustion in a thermal power plant generates a huge quantity of fly ash. Fly ash contains various categories of particles including a good quantity of cenospheres. Cenospheres are the lightest particles in fly ash. They are collected in various processes such as the sink-float method, centrifuge method, and vertical thermal flame process. The cenosphere exporter from India, Durgesh Group, uses the sink-float method to collect cenospheres from fly ash. Subsequently, they process and purify the product to ensure export quality.